INSTALLATION OF A WOOD-FIRED HEATING SYSTEM

CUSTOMER ISSUE: CHANGE OF WOOD HEATING SYSTEM

A cabinet-making company was heating its 1200 m2 workshop with a forced-convection wood-fired generator. This blew air directly into the room through 2 vents. This heating system made the workspace uncomfortable due to air movement and poor heat distribution. Some areas were without heat and required additional energy input.

CUSTOMER PROJECT: CHANGE OF WOOD-FIRED FURNACE

Construction of a new 2,500 m2 production building

CUSTOMER REQUEST: NEW, MORE EFFICIENT WOOD HEATING SYSTEM

A more efficient and comfortable generator capable of heating the entire new workshop.

OBJECTIVE TO BE ACHIEVED

Heat a 2500m2 production building using production waste, in particular wood. Operate in total autonomy and meet the building’s heating needs while ensuring comfort of use. The customer even installed a centralized extraction system, which recovers production dust and injects it into a machine. This machine produces sawdust briquettes, which play the same role as wood pellets.

SOLUTIONS PROVIDED BY POLYPOLES

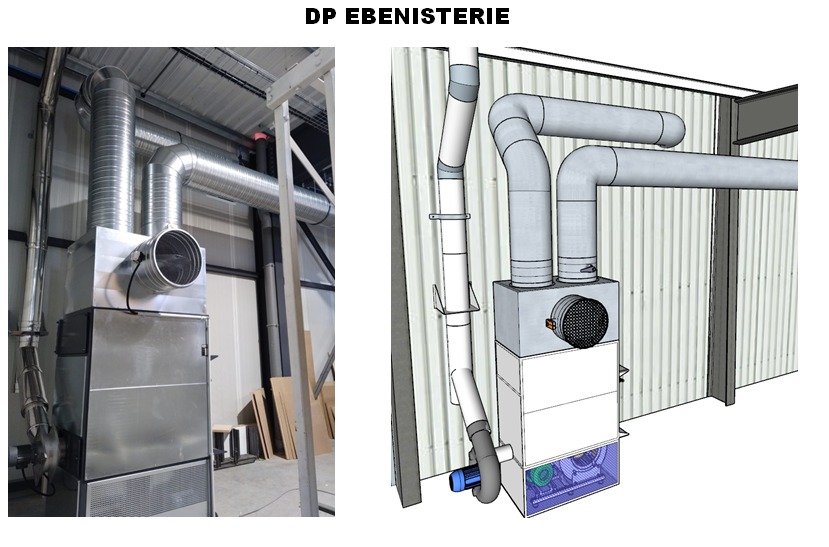

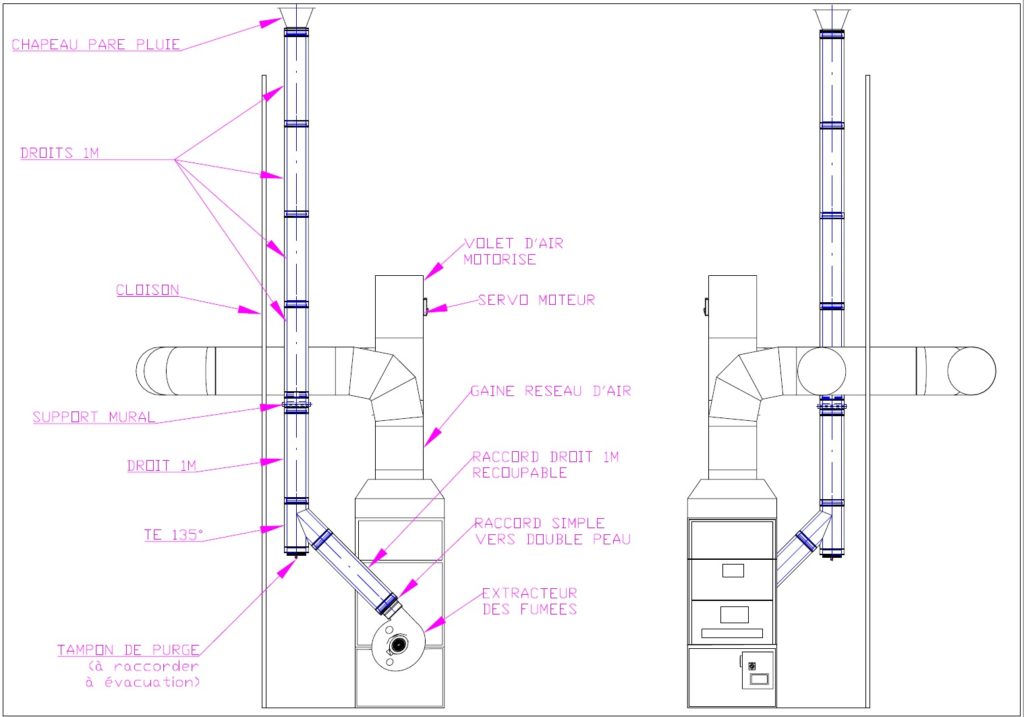

Installation of a wood-fired generator with 2 networks of perforated textile sheaths

RESULT

The textile sheath network behaves perfectly under the load of the generator. The aeraulic diffusion over the entire length of the building ensures efficient, distributed heating. The customer is delighted with the new equipment. He was able to take part in the commissioning and understand how the generator works. To find out more about these innovative solutions and how they can meet your energy needs, visit our biomass boiler page.

POLYPOLES CUSTOMIZES WOOD HEATING SYSTEMS

The installation of the equipment was facilitated by precise work by the design office. The 2D and 3D plans enabled our site team and our customer to visualize the final rendering.